Mashiinka Calaamadaha Himilada ee UV

✧ Astaamaha mashiinka

Mashiinka calaamadaynta ee CCD Vist Laser ee mashiinka calaamadaynta ee Laser waxay isticmaashaa mabda'a meelaynta muuqaalka. Marka hore, shayga sheyga ayaa la dejiyaa, qaabka wax soo saarka ayaa la go'aamiyaa, oo badeecada waxaa loo keydiyaa sidii qaab caadi ah. Inta lagu gudajiro howsha caadiga ah, badeecada waa in laga baaraandegaayaa la sawiray. Kombiyuutarka si dhakhso ah ayuu u isbarbar dhigayaa shayga isbarbar dhiga iyo meelaynta. Ka dib hagaajinta kadib, sheyga ayaa si sax ah loo baaraandegi karaa. Waxaa lagu dabaqi karaa xaaladaha sida culeyska culus ee shaqada, quudinta adag iyo meelaynta, habraacyada la fududeeyo, kala duwanaanta kala-duwanaanta iyo sagxadaha adag. Waxaa si weyn loogu isticmaalaa warshadaha kala duwan. Wadashaqayn la yeelo khadka kulanka si aad u ogaato calaamada tooska ah ee tooska ah ee laser. Qalabkan waxaa ku qalabeysan soojiidashada sawir-galka otomaatigga ah iyo calaamadeynta waxyaabaha la warshadeeyay ee ka dib ashyaada hawsha lagu dhaqaaqayo dhanka safka Golaha. Ma jiro hawlgal meeleyn ah oo meeleyn ah oo loo baahan yahay si loo gaaro hawlgalka sumadda waqtiga eber, kaas oo badbaadiya geedi socodka calaamadaha laser ee gaarka ah. Waxay leedahay hufnaan sare, sax ah, badbaado iyo isku halaynta iyo astaamaha kale ee waxqabadka sare. Awooda waxsoosaarka ayaa dhowr jeer ka mid ah mashiinnada calaamadaha calaamadaha caadiga ah, si weyn u wanaajinta hufnaanta shaqada iyo keydinta kharashaadka shaqada. Waa qalab wax ku ool ah oo taageeraya kharash-ku-meel-gaar ah oo loogu talagalay hawlgallada laser ee lagu calaamadeeyo khadka tooska ee khadka.

✧ Faa'iidooyinka dalabka

Mashiinka caqliga leh ee laser-ka ah ee lagu calaamadeeyay ee mashiinka lagu calaamadeeyay ee laser-ka ah ee laser-ka ah ee sahayda adag, meela sabool ah iyo xawaare gaabis ah oo ay sababaan dhibaatooyinka ku jira naqshadaynta iyo wax soo saarka xargaha saqafka aan caadiga ahayn. Calaamadeynta Kaamirada CCD waxaa lagu xaliyaa iyadoo la adeegsanayo kaamiro dibadeed si loo qabto qodobbada muuqaalka waqtiga dhabta ah. Nidaamku wuxuu bixiyaa agabyada waxayna xoogga saareysaa dardaaranka. Booska iyo calaamadaha ayaa si weyn u horumarin kara hufnaanta hufnaanta.

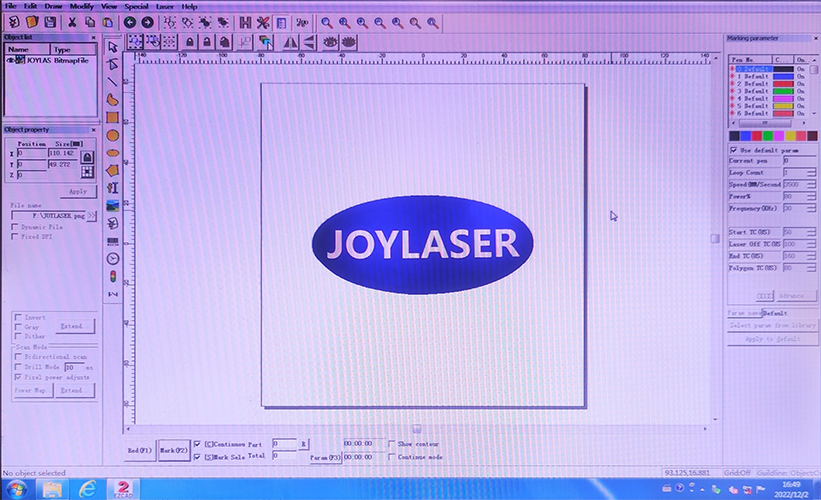

✧ Interface Howlgalka

Software-ka mashiinka calaamadaha calaamadaha ee rajeesku wuxuu u baahan yahay in loo isticmaalo iyada oo lala kaashanayo qalabka kaadhka xakamaynta calaamadaha laseed.

Waxay taageertaa nidaamyo firfircoon oo kumbuyuutar oo kala duwan oo kumbuyuutarro ah, luqado badan, iyo horumar sare oo softiweer ah.

Waxay sidoo kale taageereysaa lambarka qareenka caadiga ah iyo koodhka QR, koodaabka 39, Codabar, EEC, UPC, Dtamatrix, Dotamatrix, iwm code, iwm code, iwm.

Waxa kale oo jira sawiro xoog leh, qadhaadh xoog leh, khariidado vector, iyo sawir gacmeed iyo tafatirka hawlgallada ayaa sidoo kale soo jiidan kara qaababkooda u gaarka ah.

✧ Tilmaamo farsamo

| Moodeelka Qalabka | Jz-ccd-fiber jz-ccd-uv jz-ccd-co2 |

| Laser nooca Fiber Laser | Uv leser rf rf co2 laser |

| Laser hivlethth | 1064Nm 355NM 10640Nm |

| Nidaamka booska | CCD |

| Wajiyada muuqaalka | 150x120 (waxay kuxirantahay maaddada) |

| Pixels kaamirooyinka (ikhtiyaari) | 10 milyan |

| XUQUUQDAADA | ± 0.02mmm |

| Baaxadda ballaca wadnaha | 200NS 1-30NS |

| Soo noqnoqda laser | 1-1000khz 20-150khz 1-30khz |

| Xawaaraha khadka toosan | ≤ 7000mm / s |

| Ballaadhka ugu yar | 0.03mm |

| Waqtiga Jawaabta Waqtiga | 200s |

| Shuruudaha Awoodda | Ac110-220v 50hz / 60hz |

| Shuruudaha Awoodda | 5-40a ℃ 35% - 80% RH |

| Qaabka qaboojinta | hawo qabow hawo qaboojisay oo la qaboojiyey |

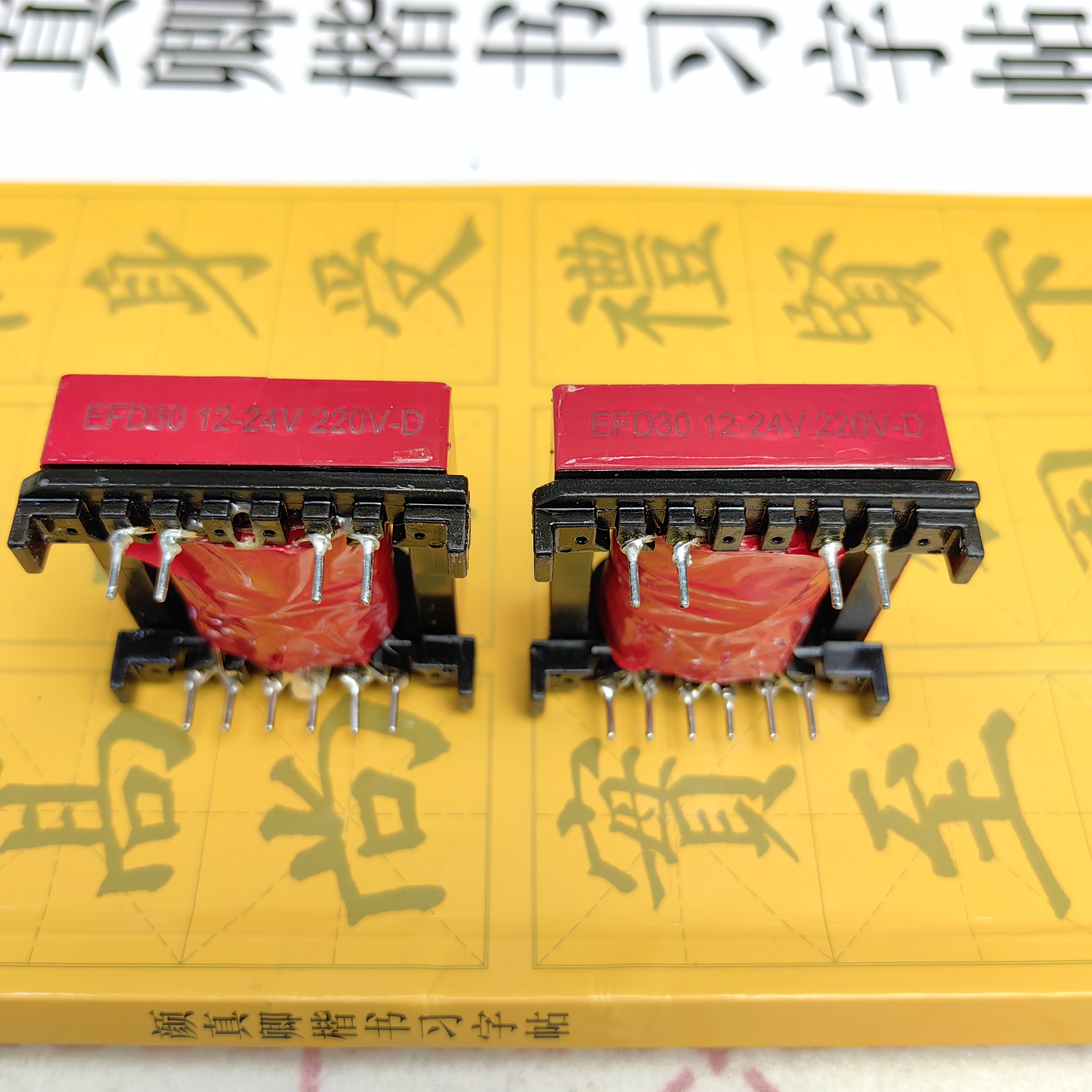

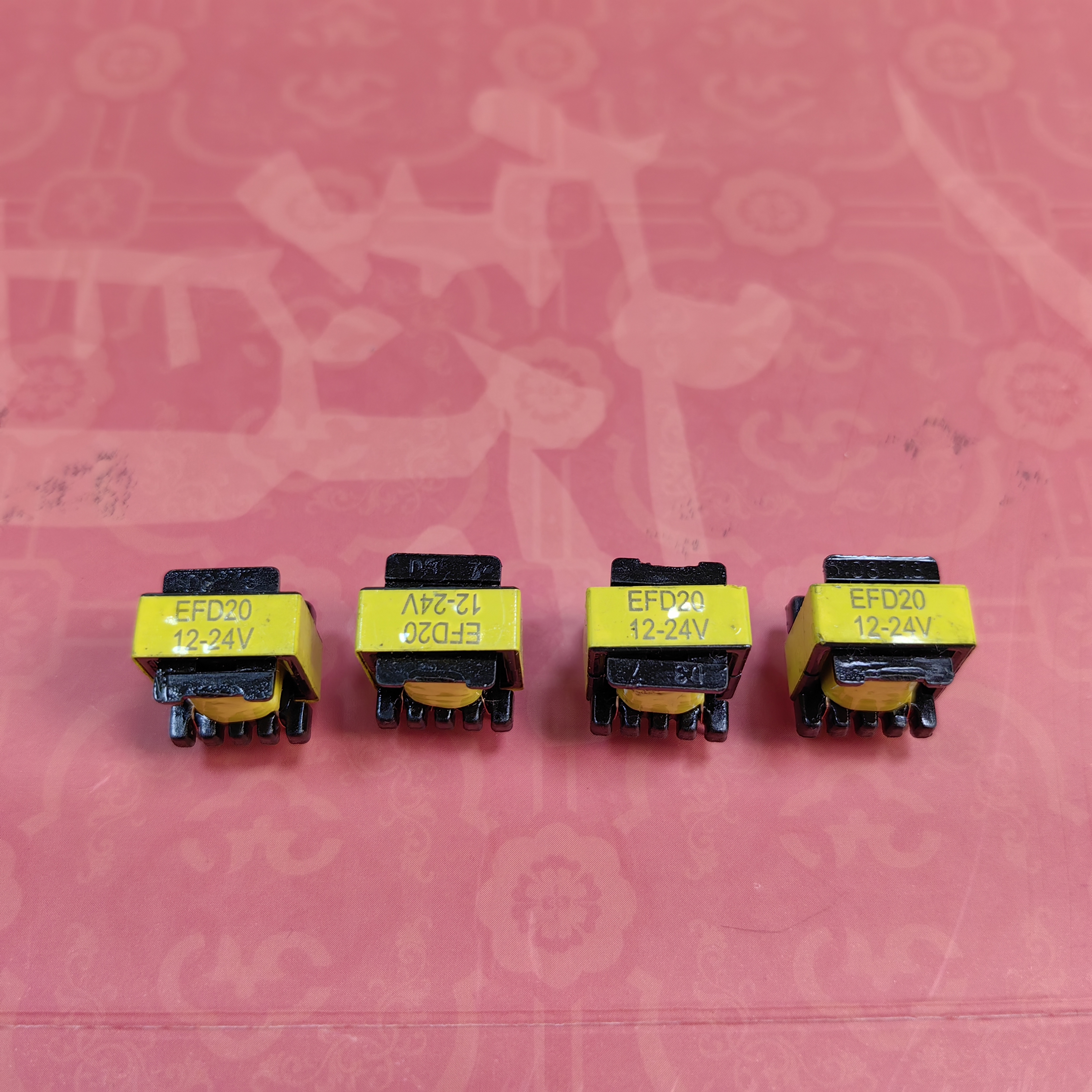

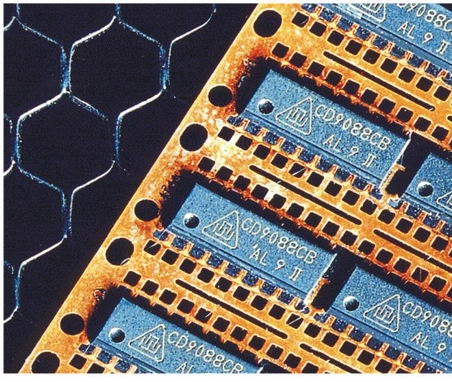

✧ Muunad badeecad ah