Wax soosaarka warshadaha casriga ah, tikniyoolajiyadda la-talinta ee laser ayaa noqotay habab muhiim ah oo loogu talagalay shirkadaha badan si loo wanaajiyo tayada calaamadaha astaamaha iyo hufnaanta waxsoosaarka oo ay sabab u tahay faa'iidooyinkooda sida saxda ah, xawaaraha sare, iyo kuwa aan la xiriirin. Noocyo badan oo ka mid ah mashiinnada calaamadaynta laser, makiinadaha calaamadaynta ee Mopa Laser Laser iyo mashiinada sumadda ee caadiga ah ee Fiber waa laba nooc oo caadi ah. Fahmitaanka farqiga u dhexeeya iyaga waxay muhiim u tahay doorashada qalabka ku habboon baahiyaha soosaarka qofka.

Marka hore, bal aan fahmeyno mabaadi'da shaqada ee labadan nooc ee mashiinnada calaamadinta laser-ka ee laser. Mashiinnada calaamadaynta Fiber ee caadiga ah ee caadiga ah ee si toos ah wax soo saarka laser iyada oo loo marayo fiber lasers, iyo mawjadaha jilicsan ee laser-ka waa la xalliyaa. Si kastaba ha noqotee, makiinadaha calaamadaynta Mopa Laser Laser waxay qaataan qaab dhismeedka Oscillator-ka Sawirka iyo Awooda Power, oo u saamaxday isku-habeyn dheeraad ah oo kacsan ee ballaca wadnaha iyo soo noqnoqda.

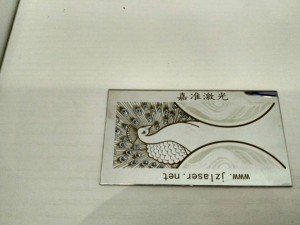

Marka laga hadlayo astaamaha waxqabadka, oo ay ugu wacan tahay hagaajinta ballaca wadnaha ee garaaca wadnaha iyo makiinadaha calaamadaynta ee Mopa Laser Laser waxay gaari karaan saameynta wanaagsan ee calaamadaynta, sida abuurista calaamadaha midabka ee bir bir ah. Taa bedelkeeda, saameynta calaamadaynta mashiinnada calaamadaynta Fiber ee caadiga ah ee caadiga ah waa mid fudud.

Tusaale ahaan, warshadaha elektiroonigga ah, mashiinada calaamadaha super ee caadiga ah waxaa badanaa loo isticmaalaa calaamadaynta sahlan ee qolofka taleefanka moobaylka; In kasta oo mashiinnada calaamadaynta ee Mopa laser loo isticmaali karo in lagu calaamadiyo wareegga yar yar ee ku yaal chips. Warshadaha dahabka ah, mashiinada calaamadaha sumadda ee caadiga ah ayaa guud ahaan loo isticmaalaa in lagu calaamadiyo qaababka aasaasiga ah ee dahabka dahabka, iyo mashiinada calaamadaynta ee Mopa laser-ka waxay ku guuleysan karaan qaab adag iyo qaab dhismeedka qoraalka.

Sida laga soo xigtay warbixinnada cilmi-baarista ee laxiriirta, maadaama shuruudaha lagu calaamadeeyay badeecada ee warshadaha wax soo saarka ay sii kordhayaan, wadarta suuqa ee mashiinnada calaamadaynta ee Mopa Laser si tartiib tartiib ah ayuu u sii fidaa. Mustaqbalka makiinadaha calaamadaynta ee Mopa Laser Laser ayaa la filayaa in si weyn loogu isticmaalo beero soo-saar badan oo soosaarid badan, halka mashiinada calaamadaha fiber laser ee caadiga ah ay sii wadi doonaan inay ka faa'iideystaan xaaladaha qiimeynta aasaasiga ah qaarkood.

Gabagabadii, waxaa jira farqi muuqata oo u dhexeeya mashiinnada calaamadaynta ee mopa leser laser iyo mashiinnada sumadda ee caadiga ah ee lagu calaamadeeyay mabda 'shaqo, astaamaha waxqabadka, xaaladaha waxqabadka, qiimaha, iyo dhimista dayactirka. Markii la xusho, shirkadaha shirkaduhu waa inay si kooban u tixgeliyaan arrimo kala duwan oo ku saleysan baahiyadooda wax soo saarkooda iyo miisaaniyaddooda oo ay doortaan qalabka ugu habboon ee lagu calaamadinayo kuwa ku habboon. Waxaan rajeynayaa in iyada oo loo marayo in la soo bandhigo qodobkan, waxay kaa caawin kartaa inaad fahanto farqiga u dhexeeya labadan nooc makiinadaha calaamadaha laser-ka ee laseed si cad oo u siiya tixraacyo waxtar leh go'aannada wax soo saarka ee wax soo saarka.

Waqtiga Post: Jul-03-2024